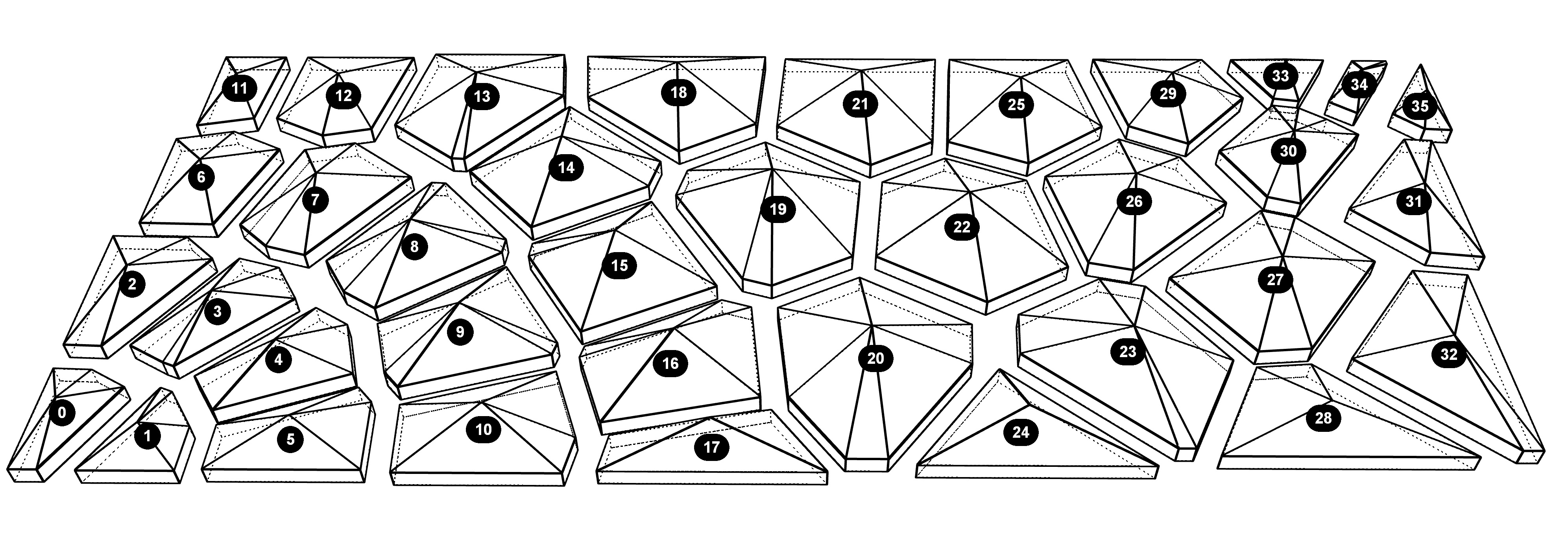

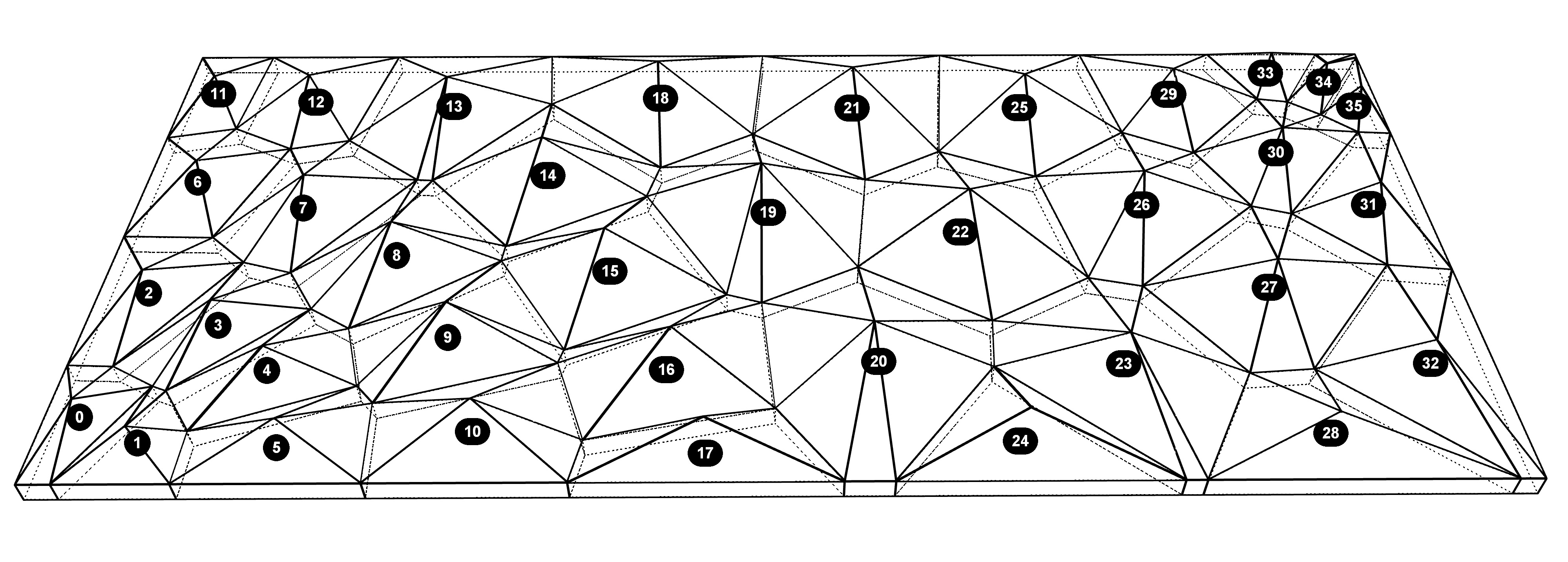

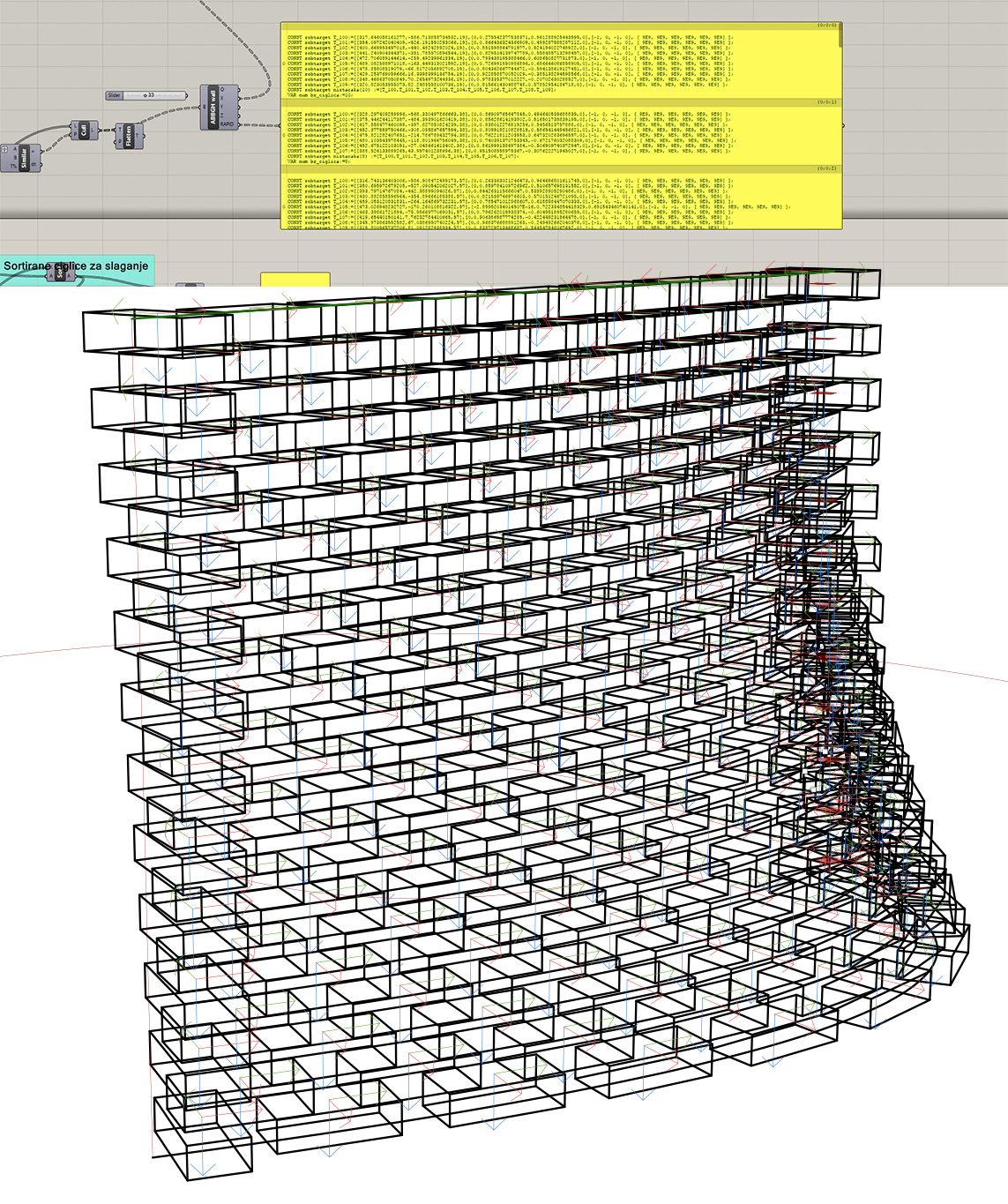

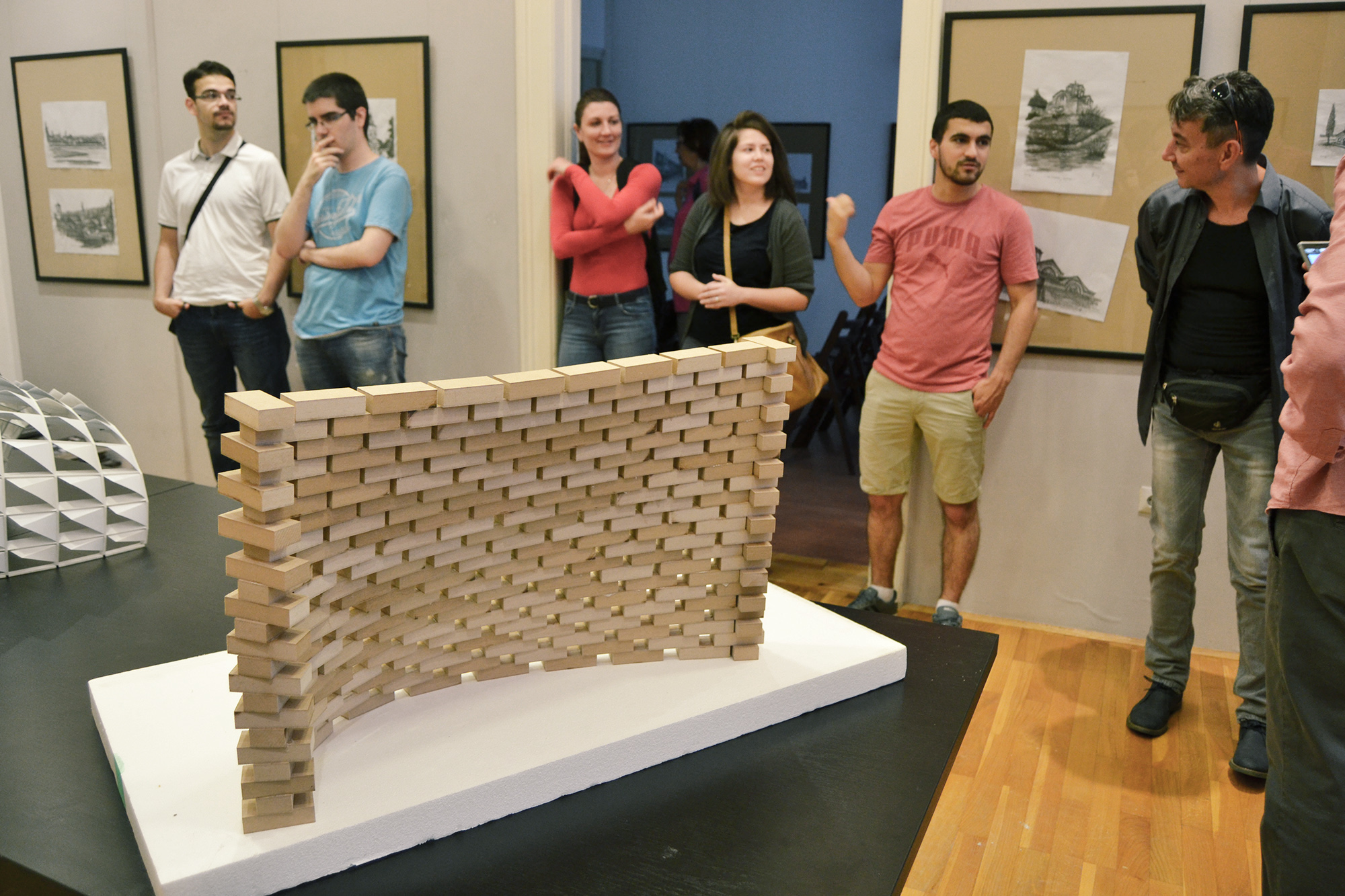

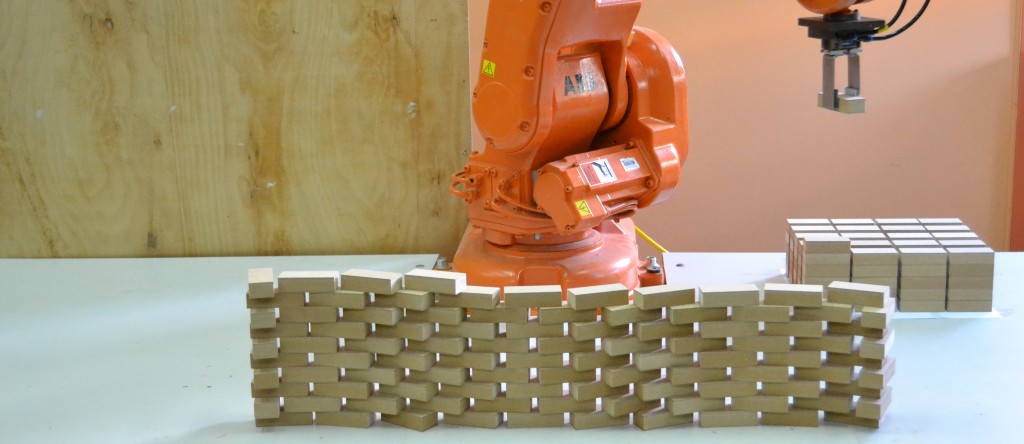

Diamond wall is project designed for the 15th aniversary of Austrotherm in Serbia and fabricated in foam with industrial robot. Diamond wall consists of 40 piramidal shaped EPS blocks arranged with parametric controlled radial pattern based on distribution of points (voronoi cells). One of the major challenges were size fitting of blocks to the working area of ABB IRB 140 robot and its custom design hotwire cutter tool.

Credits: Marko Jovanović, Dejan Mitov, Jovica Tasevski, Mirko Raković, Bojan Tepavčević, Vesna Stojaković, Ivana Bajšanski