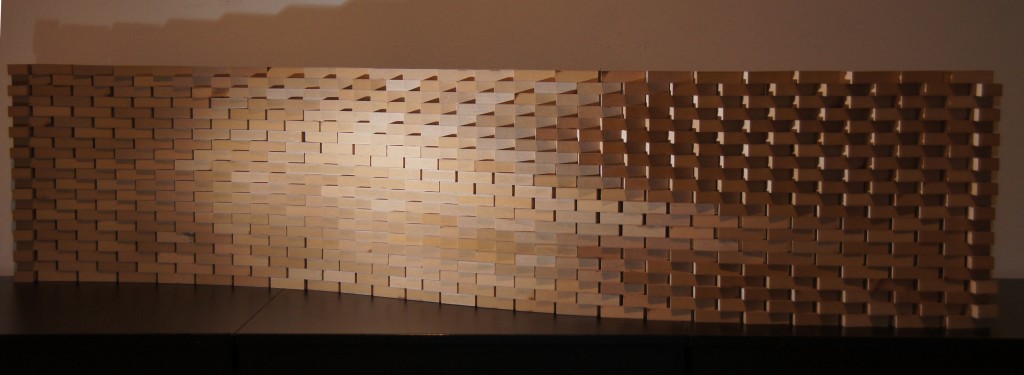

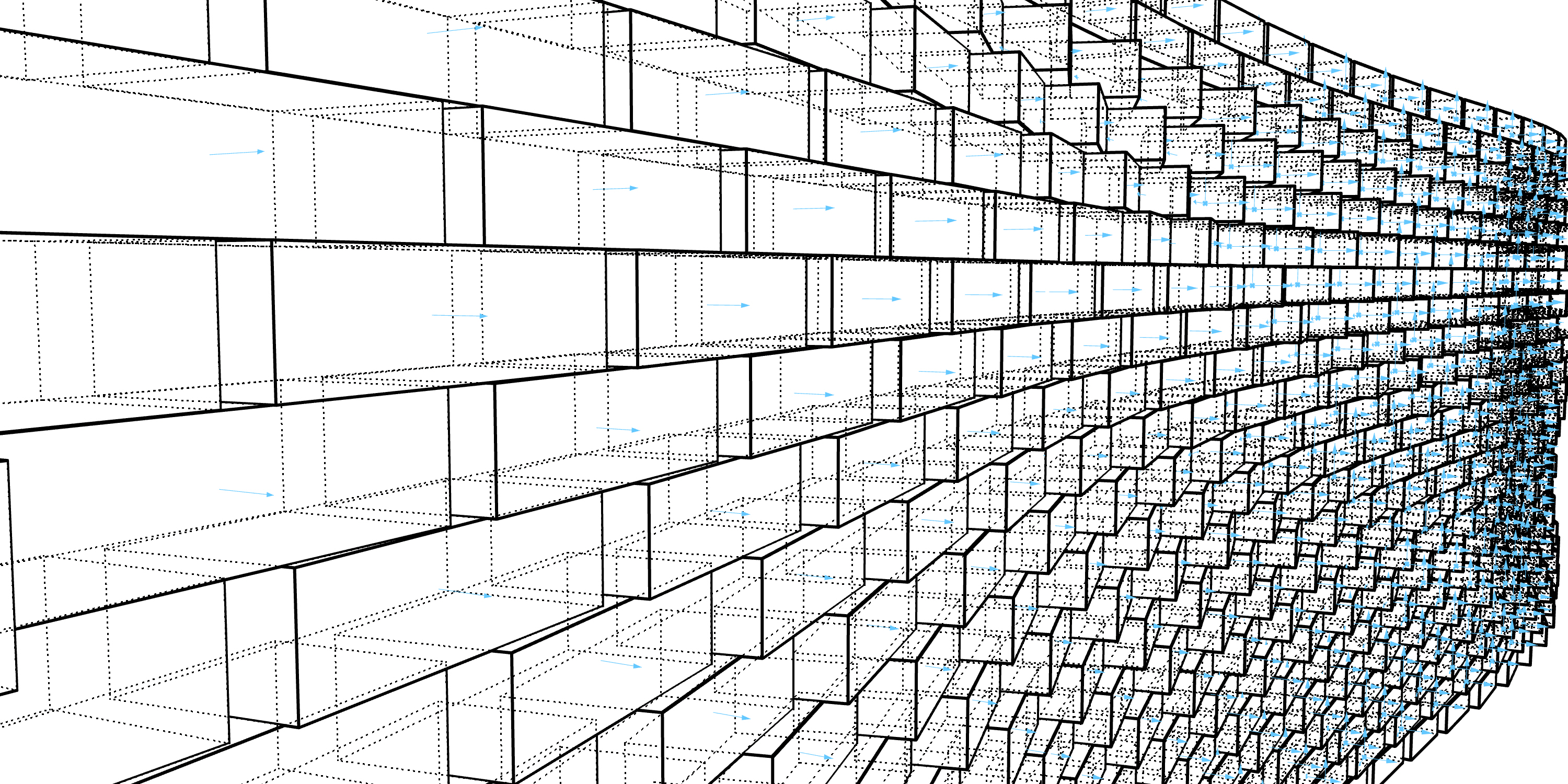

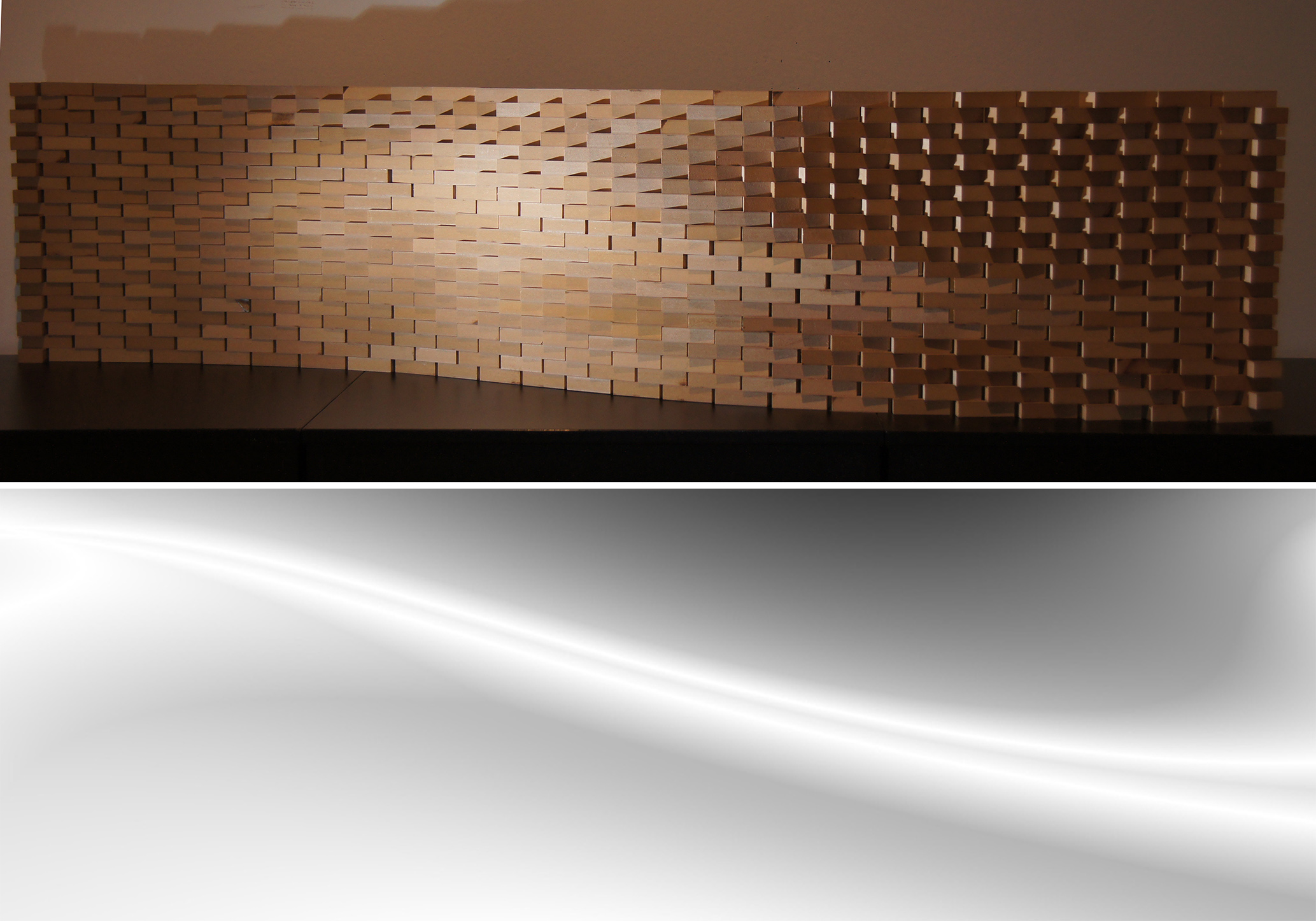

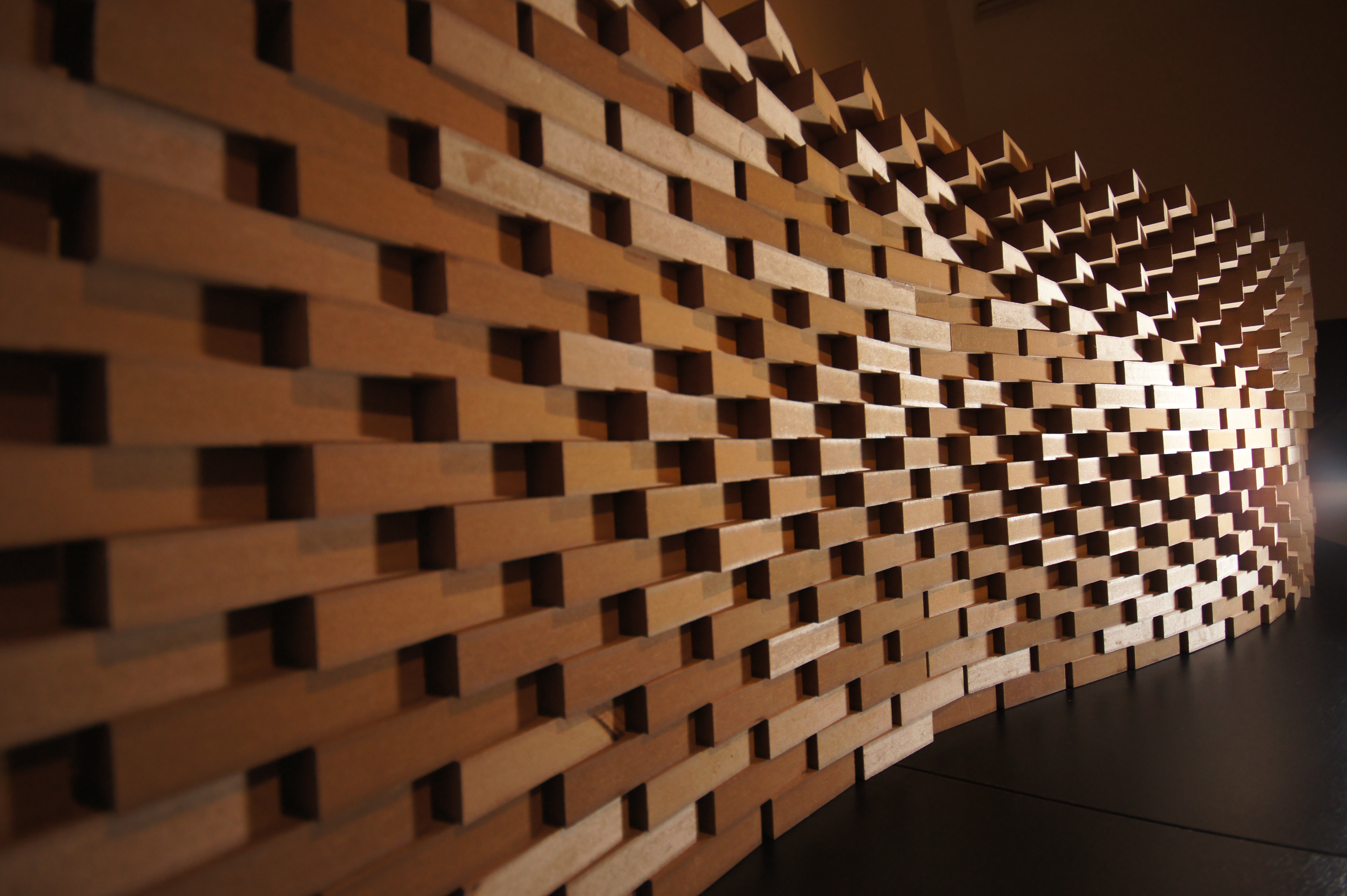

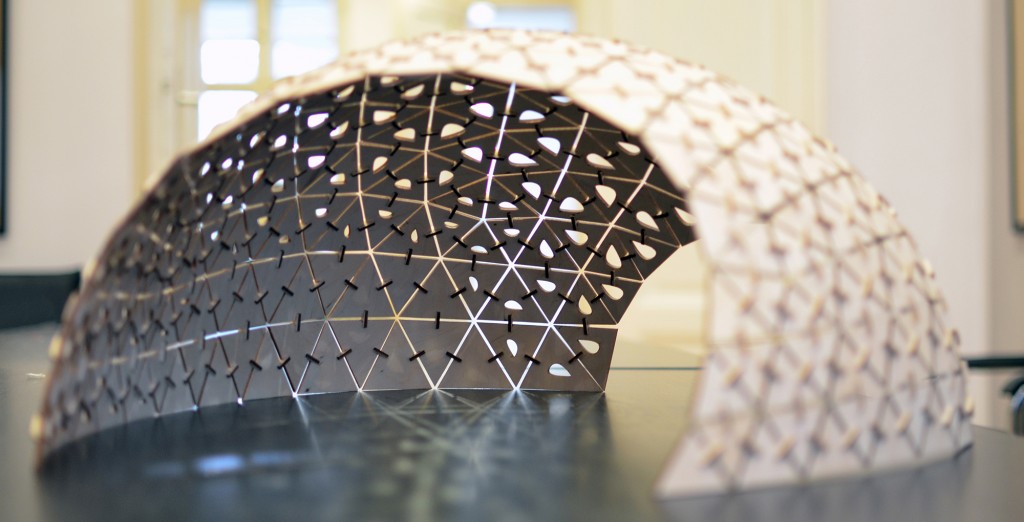

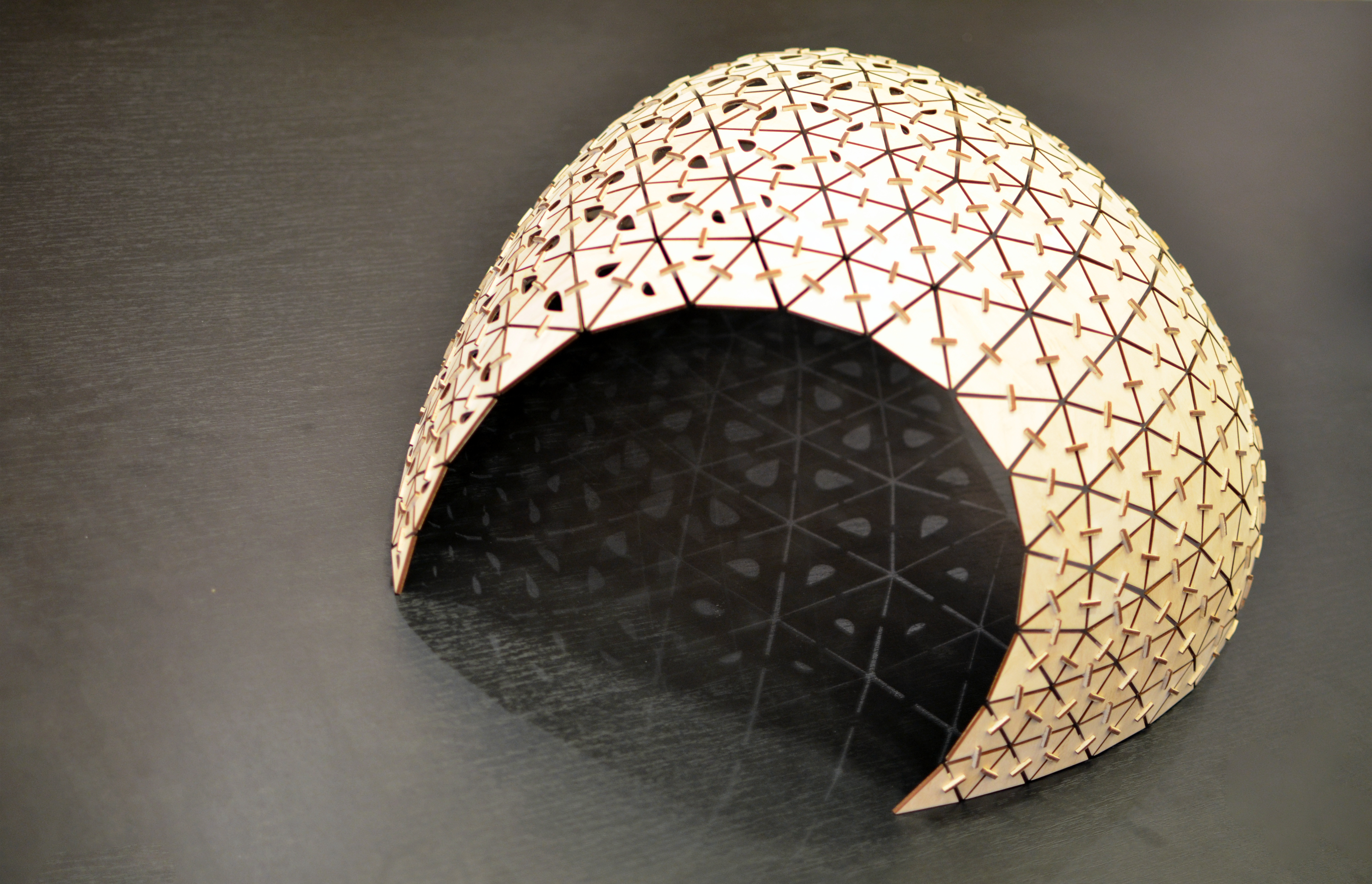

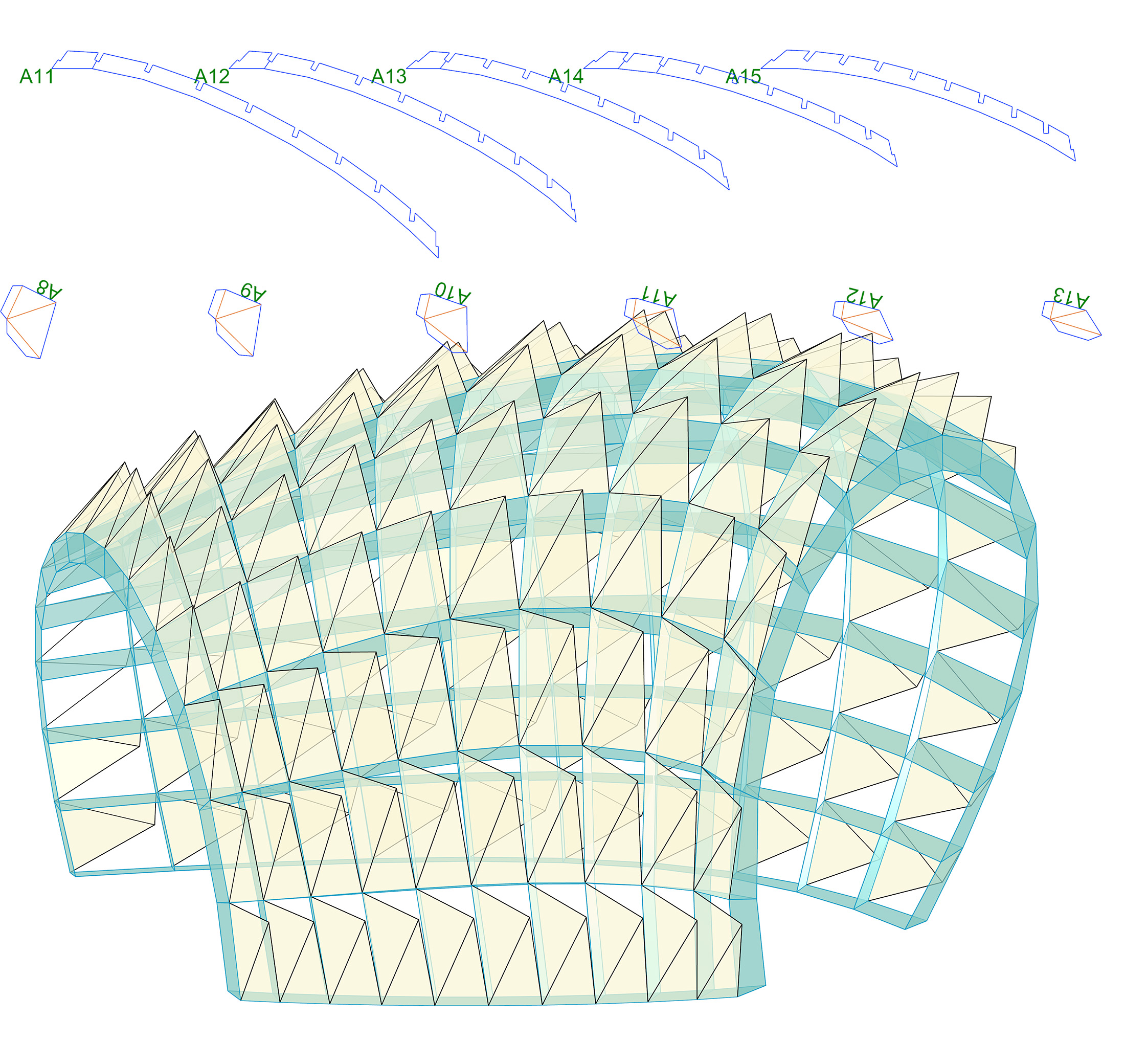

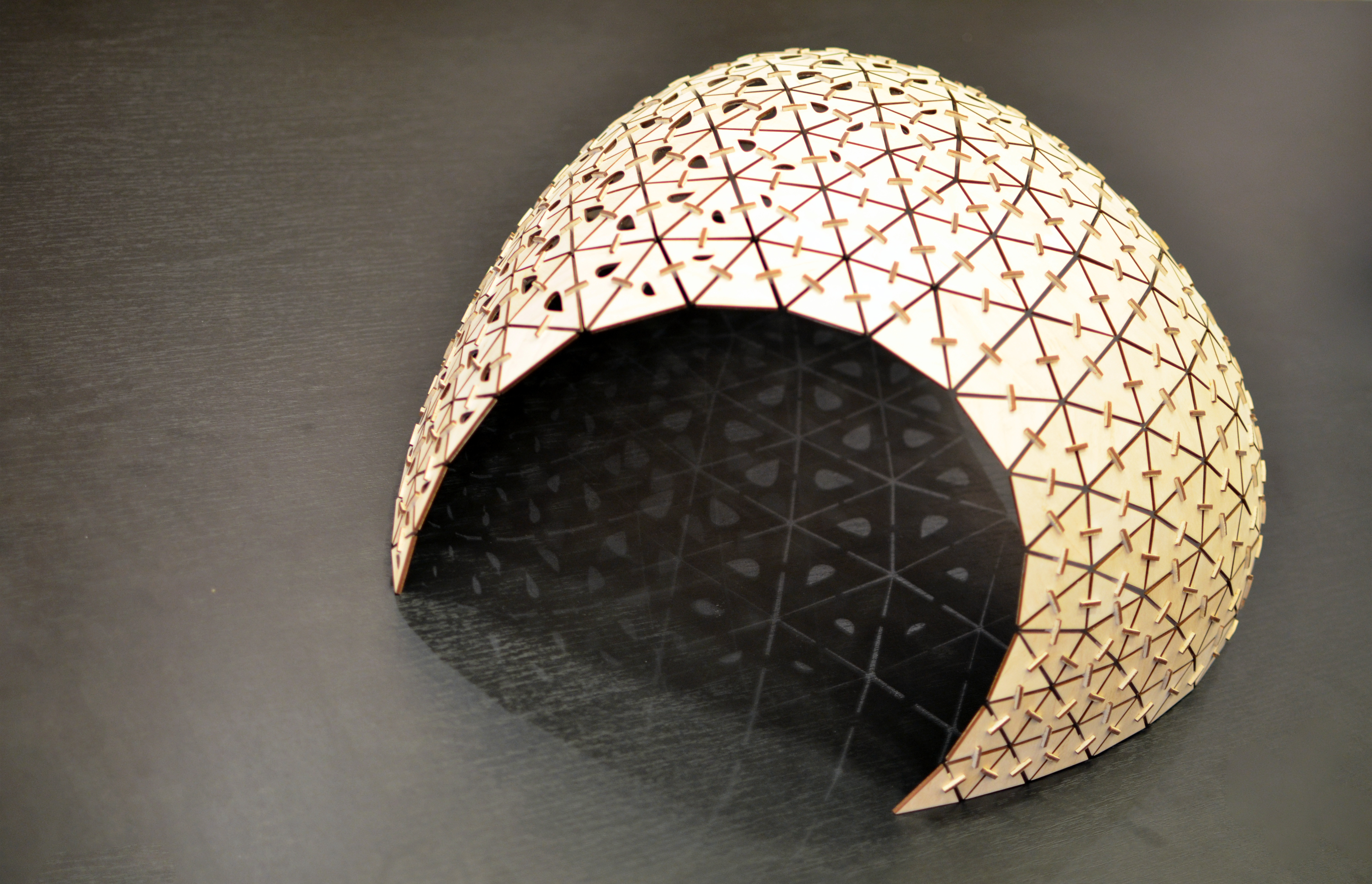

The Triangle pavilion combines tessellation design logic with friction fit connection system that does not need glue or mechanical fasteners. Pavilion form is geometricaly optimized via Evolute tools with greater influence of sphere packing algorithm in order to get torsion-free nodes and equilateral triangle look. On the other side connectors distributed at the mid-edge of the triangles provide hexagonal pattern on the overall shape. Additionally openings are distributed on such way to gradually provide vistas from enclosed space. Design is tested with scale model and prototype is expected to be realized at Unitec Institute of Technology, Auckland, New Zealand on September 2015.

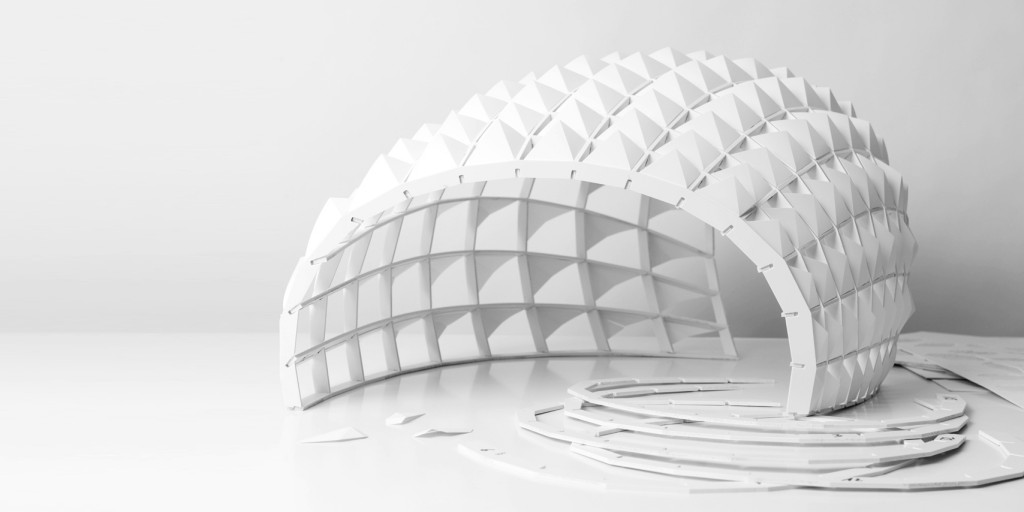

Test for full scale fabrication, UNITEC Institute of Technology, Auckland, New Zealand

Starting full scale fabrication, UNITEC Institute of Technology, Auckland, New Zealand

Credits: Bojan Tepavčević (design), Dejan Mitov (Model making), Digital Design Center, FTN, University of Novi Sad